Production

HOW WE CAN HELP…

In a competitive world market, the way to stay ahead of the competition is to do it better for less. Camcar Plastics Inc does just that. Our experience, dedicated staff and trained personnel work as a team to provide excellent quality, service and delivery at reduced costs. Our lean principles and business model opens doors to add new business and customers. We are competitive in the world market in high volume plastic part production.

ALL FACETS OF PRODUCTION…FROM PRODUCT TO FULFILLMENT

SCIENTIFIC PRODUCTION MOLDING

Whether making 1 part or 25,000,000 parts, Camcar Plastics, Inc. has a proven system of checks and balances to make sure your parts are produced correctly and on time. All employees have successfully completed rigorous injection molding training by Paulson.

PLASTIC MATERIALS

Camcar Plastics Inc, uses thermoplastic materials; both engineering and commodity grades. There are numerous grades and options for plastic material choices, plus new, innovative products are readily available.

An example of the products processed and manufactured here are polyethylene (both HDPE & LDPE), polypropylene, ABS, PC/ABS, Nylon, Acrylic, Acetal, polyester, polystyrene, PPO, PPS plus thermoplastic rubbers. In addition to these grades, purpose-driven materials are offered including food grade, medical grade with UL yellow card listings and automotive grades. These products are available with additives for strength and other disciplines. Some additives we process include glass (both short & long fiber), carbon, conductive, non-conductive, anti-static, fire retardant, lubricative, wear resistant, talc, calcium, UV stabilizers and more. Colors available are any color in the rainbow.

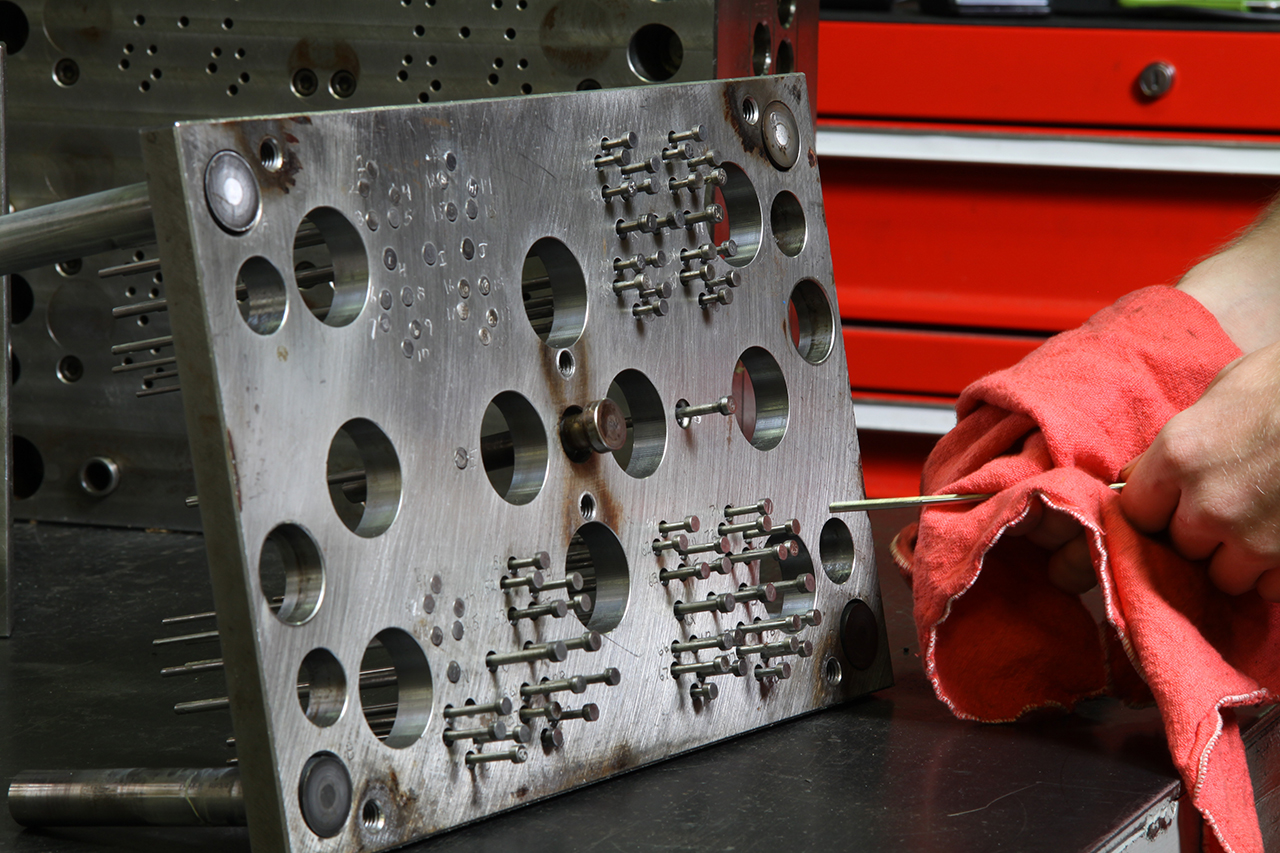

PERFORMANCE TOOLING FOR PLASTIC MANUFACTURING

Not to be taken lightly; High quality plastic injection molding tooling. The Key ASSET VALUE for quality tooling; Advanced tool design standards, balanced runner systems, effective cooling channels, scientific venting, preferred gating (sizing, location and type), tight tolerances, technical slides and lifters, correctly drafted cores (fixed, floating, collapsible), cold & hot runners, tips, systems. Steels types: Aluminum, Steel and hardness options (420, P-20, H-13, S-7). Prototypes; recommended! Rapid prototypes; SLA, SLS, machining and more options with a quote request. MUD frames also standard.

PLASTIC PARTS DESIGN AND TOLERANCES

Plastic part design and material choice will define plastic parts tolerance and quality. Consulting is included and recommended. Many unknowns will happen when not cultured in the plastic injection industry. How we solve the following problems is education, knowledge, experience and scientific approach. Problems that can occur include; warp, non-uniform part shrinking, parts not to print, sinks, deformations, trapped gas, flow lines, weakness, jetting, burning, discoloration, brittleness, delamination, flash, gate blush, weld lines, voids and more. Tolerance of +/- .001” and high quality is possible with team Camcar Plastics Inc.

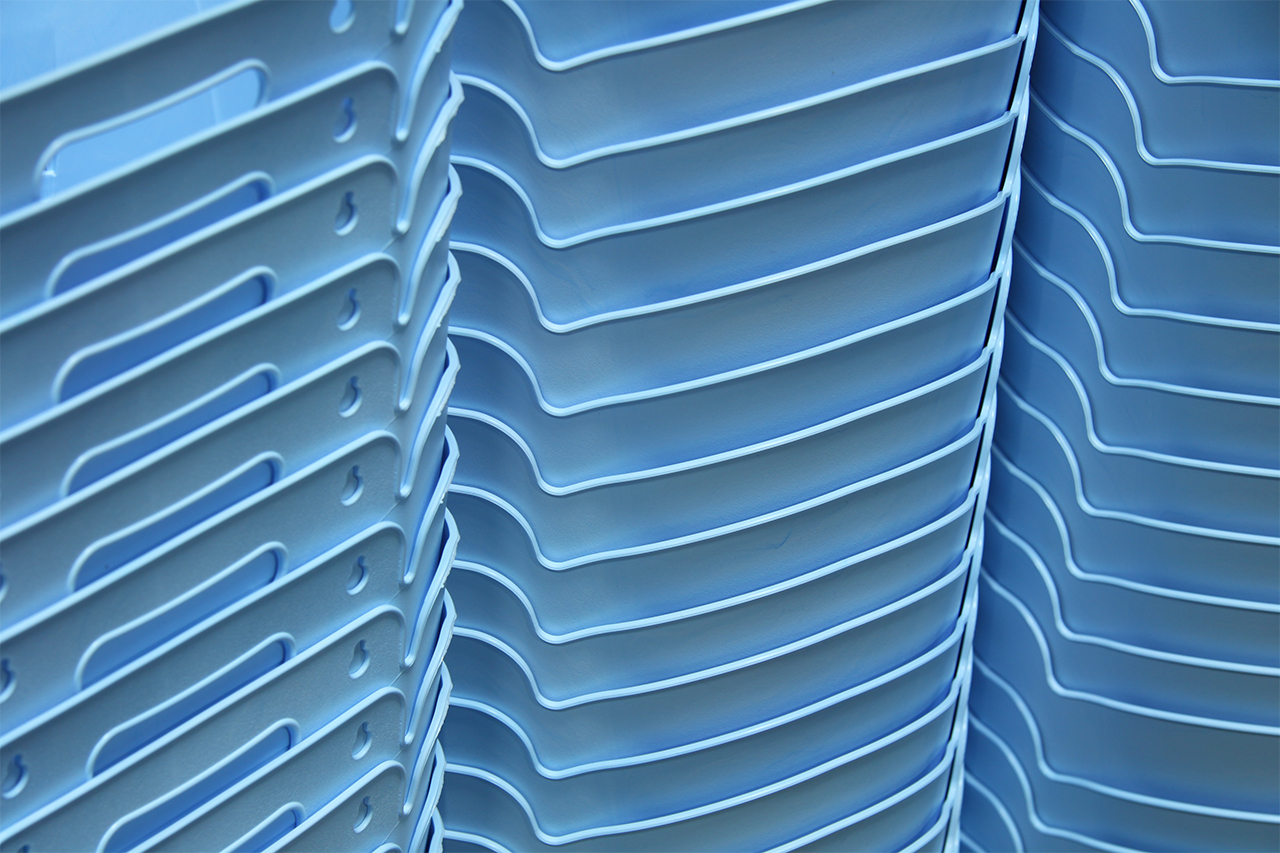

PLASTIC PART ASSEMBLY & KITTING

Camcar Plastics Inc is a Full-service plastic injection molding company that completes tasks to help other companies stay competitive with their products. Every time a part or product is touched it costs money? Making plastic parts in conjunction with other tasks saves time and money. Our team will add value by drilling holes, threading holes, applying tapes, packaging, kitting, assembly and more.