Services

Plastic Injection Molding Services – From Concept to Completion…

Camcar Plastics Inc is a full service plastic injection molding company. We “specialize” in high volume plastic parts production using multi-cavity tooling. We are also capable of insert molding, over-molding, and in-mold threading. Beyond that, we perform secondary operations including, pressing inserts in plastic parts, applying adhesive tapes and others…

High & Low Volume Plastic Injection Molding Services

» Injection Molding

» Quality Standards & Practices (Policies & Procedures ISO-9001)

» Tooling Services

» Tight Tolerances

» Low Overhead – Cost Efficient

» USA Production Shipping to USA / World Market

QUOTING, CONSULTATION & PROTOTYPING

PLASTIC PART QUOTING

Camcar Plastics Inc will take your plastic part design and will review part design, material and yearly volume.

“FREE QUOTING” – no obligation.

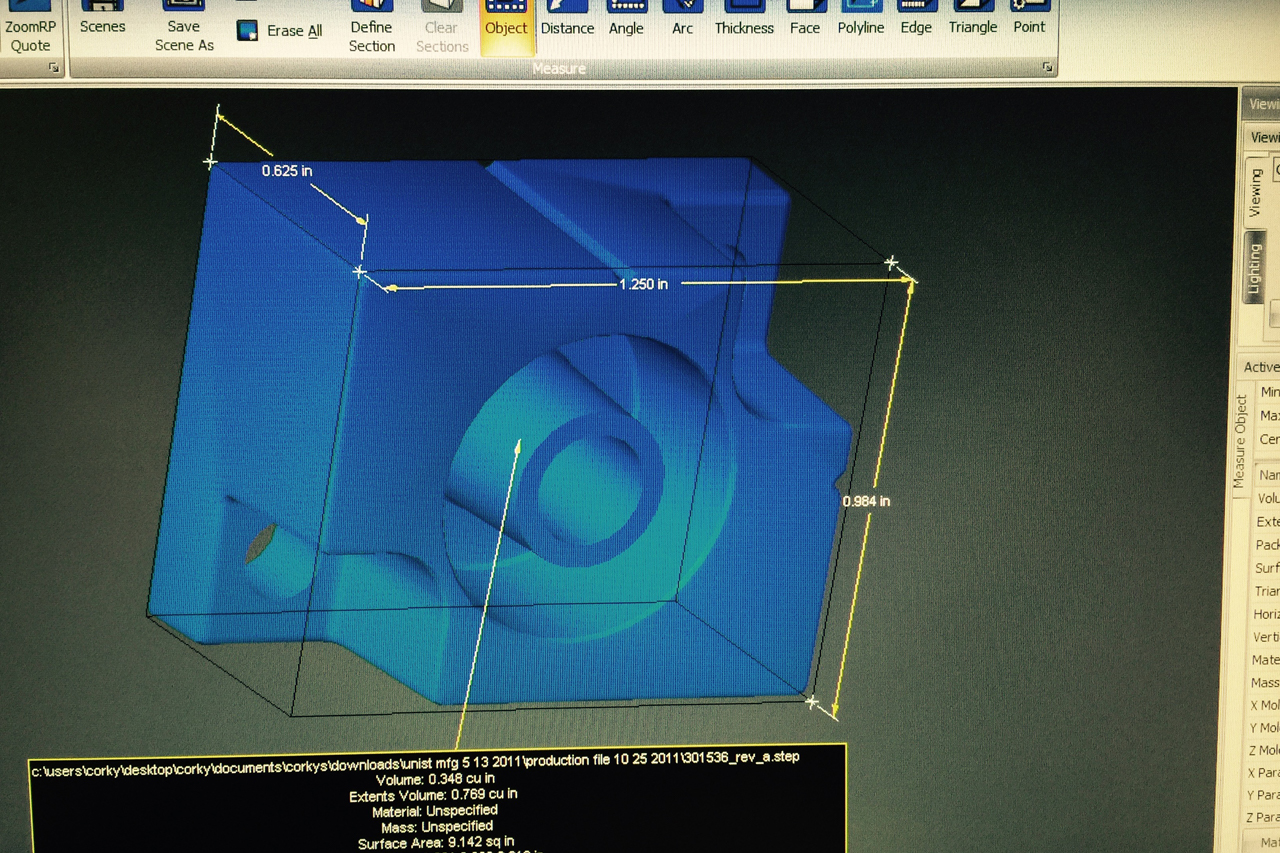

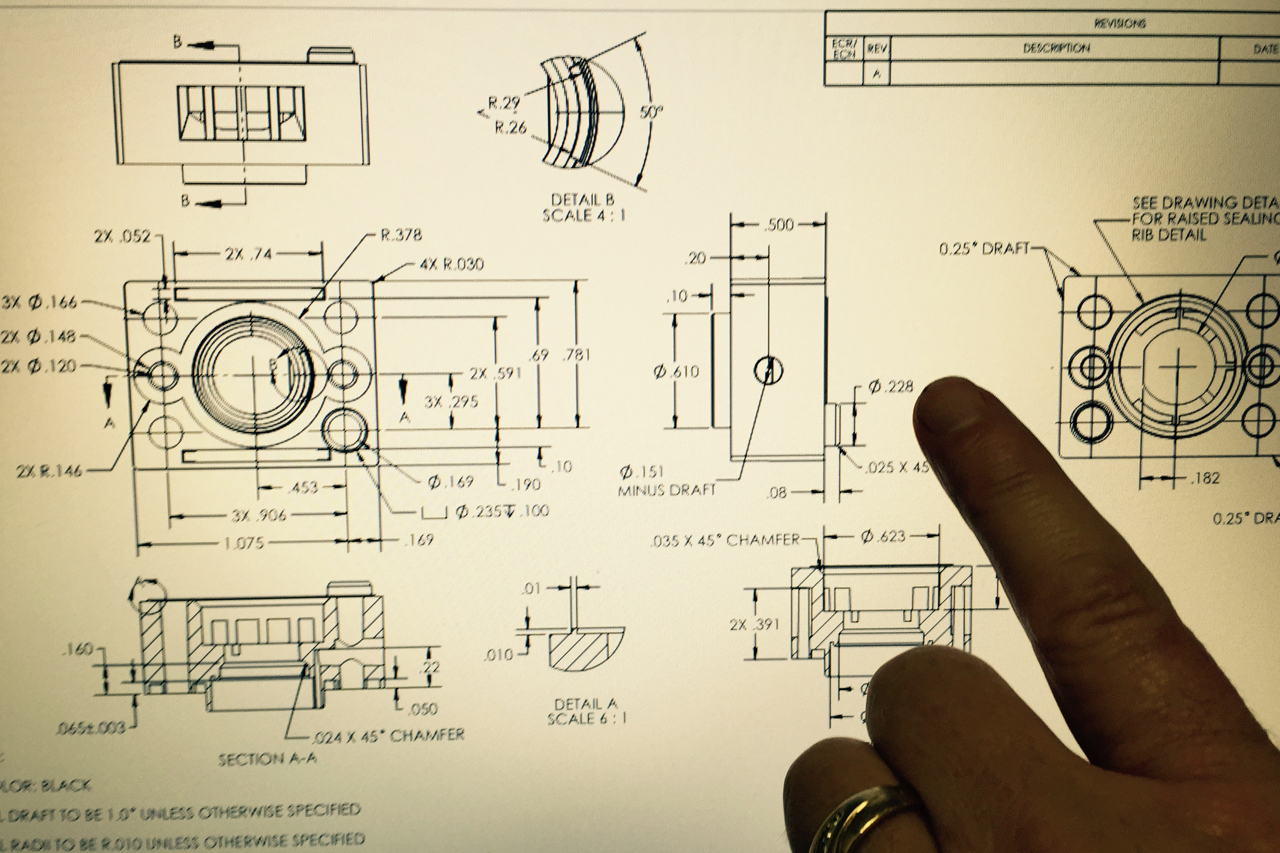

Needed: 3D part file (and preferably a part print), material specification and estimated yearly part usage.

PLASTIC INJECTION MOLDING CONSULTATION

Advice on practical part design concepts!

Material selection: Commodity resins versus engineering resins.

Part forming: Warping, ribs and strengths.

Tolerances: Measurements and what to expect.

PLASTIC INJECTION MOLDING

PROTOTYPING

Its always a good idea to prototype your part before a production tool is made.

Other Services: Rapid prototyping, machining, SLA services.