TOOLING

Plastic Injection Tooling Services

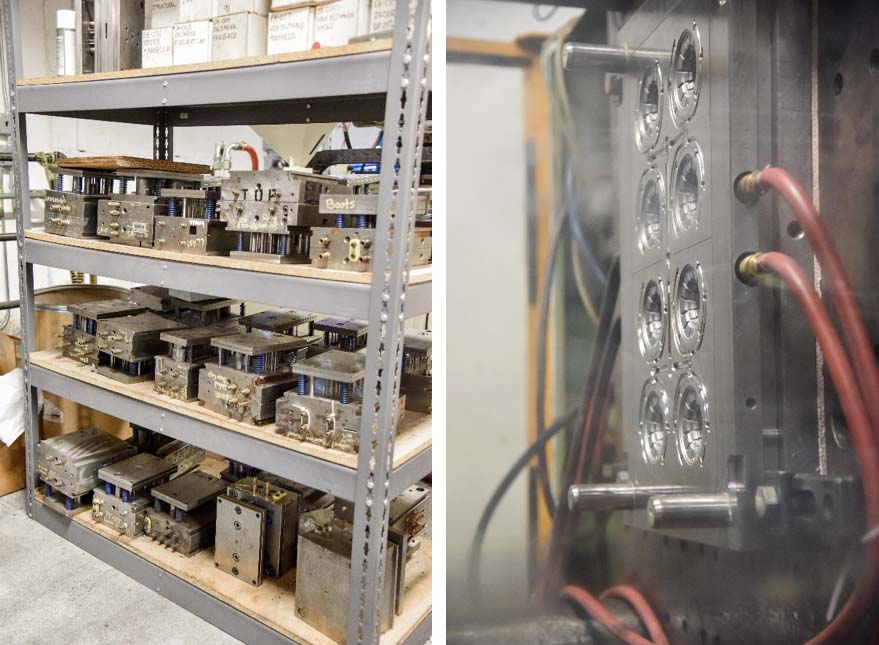

Tooling is a very important aspect of plastic injection molding and cannot be taken lightly! Camcar Plastics Inc chooses only highly qualified tool shops to make its customers plastic injection molding tools and the shop chosen has to do with the complexity and tolerances of the plastic part. Quality plastic parts require quality plastic injection mold tooling. The number of cavities in the plastic injection molding tool is determined by the annual usage of the plastic part. Plastic injection molding tooling can run from 1 cavity to, 4, 16 or 32 cavity tools and more.

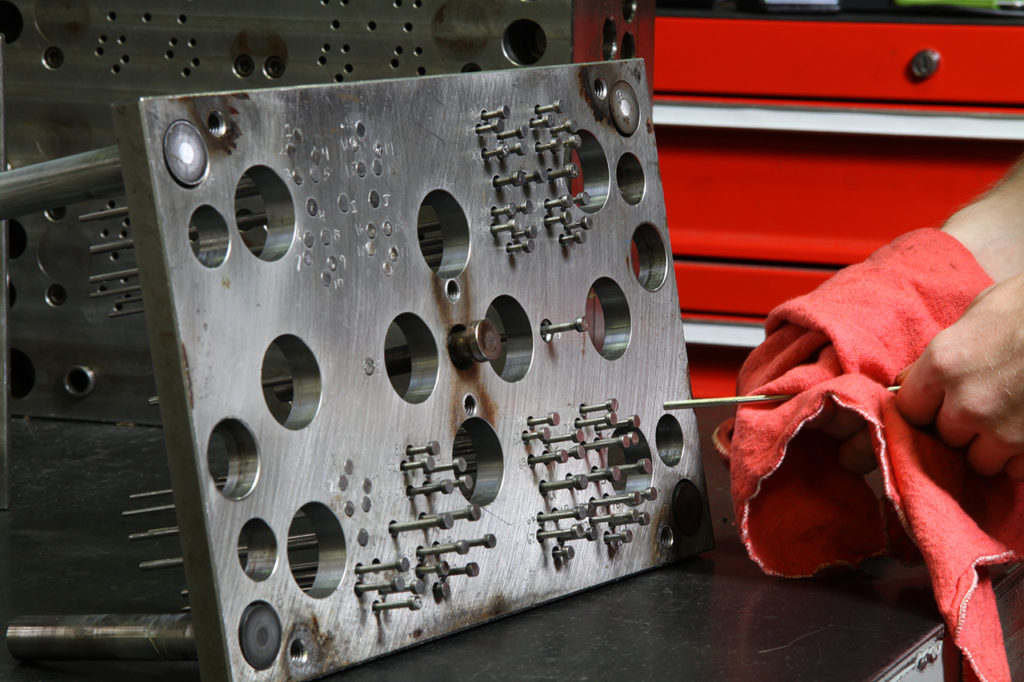

After the plastic injection tooling is made and parts are run it doesn’t end there. Camcar Plastics Inc has a rigorous maintenance program that maintains the expensive asset so it will last for the duration of the program which could be 5 years or 20 years. It is wise to pick a plastic injection molder that has your best interest! Protecting that tool to go the extra mile is a priority.

» Preventative Tooling Maintenance Procedures & Schedules

» Predictive Tooling Maintenance Procedures & Schedules

» Team of Professional Tool Makers

» Team of Professional Tool Setters and maintenance crew

» Top of the Line Protective Products

» Preferred Greases, Springs, Slides, E.J. Pins & Accessories

Tooling FAQ’S

How many cavities are needed to meet my plastic part needs?

Camcar Plastics Inc will determine the amount of cavitation needed to meet your yearly volume requirements. From single cavity to multiple cavitation, Camcar Plastics Inc does it all. We also provide tooling with slides, collapsible cores, core pulls, un-threading, hot runners and more.

Can your plastic molding process be animated?

Camcar Plastics Inc automates the process when it makes sense. Innovation and automation are used in high volume production to save costs and improve quality (robots, sprue pickers, material loaders, assembly, pad printing).

What size plastic injection molding tool can we handle?

Camcar Plastics Inc can handle tooling from small MUD molds(above), to large molds that fit into a 500-ton press size. Tooling is very a important aspect to plastic part quality and costs.

Types of steels for tooling?

Is cooling important in plastic injection molding?

Cooling or heating a plastic injection molding tool is very important and often overlooked. Camcar Plastics Inc carefully consults with the tool maker to insure the tool design has effective water lines and flow channels to maximize cycle time efficiencies. Camcar Plastics Inc incorporates preventative and predictive maintenance schedules to insure your tools are protected, checked and greased throughout their life cycle.